Home » Posts tagged 'plumbing'

Tag Archives: plumbing

Liquid Waste Disposal

Liquid Waste Disposal Perth involves following regulations and safe practices to protect the environment, human health, and infrastructure. Failure to follow proper disposal methods can result in hefty fines and legal action.

First, the liquid waste must be stored until a disposal service can collect it. Storage facilities must be designed to prevent leaks and spills and meet specific safety standards.

Liquid waste disposal can be a complex and costly business operation. This is because of the multiple environmental and regulatory considerations that must be addressed. However, there are cost-effective solutions that can help you save money. These strategies include implementing risk assessments and developing site-specific solutions based on thorough environmental impact assessments. Additionally, reducing energy-intensive treatment procedures can lower overall costs.

Companies that produce liquid waste should set up measures to contain it before either treating it onsite or sending it to the dump. This ensures that the waste does not end up in the environment, where it can cause harm to the local community and the business itself. For example, untreated waste water can leak into underground systems and contaminate the groundwater. This polluted water is called leachate. It can also leak into the soil and contaminate surface water. If it comes into contact with humans, it can lead to a variety of health problems.

The cost of waste disposal depends on the type and volume of liquid waste. Hazardous waste, for instance, typically costs more to dispose of than non-hazardous waste. This is because hazardous waste requires special treatment and handling procedures to minimize risks. Additionally, hazardous waste may need to be transported to the landfill in sealed containers. These containers must be emptied and disinfected before they can be released into the environment.

Other important factors that affect the cost of liquid waste disposal include the size and location of the facility, the number of personnel involved, and the type of waste. For instance, larger facilities that have more than one disposal tank will usually pay higher rates than smaller facilities. The cost of waste disposal can be further increased by state surcharges or additional fees charged for dumping hazardous materials in landfills. It is crucial for businesses to understand the total cost of liquid waste disposal to budget accordingly.

Hazardous Waste Manifests

Many types of liquid waste are toxic, flammable, or corrosive. They can damage the environment and public health if not managed properly. Fortunately, the right treatment and disposal techniques can minimize environmental risks. The first step is identifying the type of liquid waste, which involves conducting laboratory tests to determine its chemical makeup. This information is used to select the most appropriate disposal method.

Once the waste is ready for transportation, a hazardous waste transport company can prepare and submit a Uniform Hazardous Waste Manifest (EPA Form 8700-22). This document requires signatures from all parties involved in the transport and disposal process. It provides critical accountability to ensure that waste handling practices align with strict regulatory standards. It also helps prevent illegal dumping and deters mishandling of hazardous waste during transportation.

The EPA has established a cradle-to-grave system to track and manage hazardous liquid waste from generation through final disposal. This system includes a national electronic hazardous waste manifest (e-Manifest) system that simplifies the submission process. While paper manifests are still allowed, the e-Manifest system offers several benefits.

It also helps the EPA to quickly identify and address any issues that may arise. This can prevent violations and fines, which can cost a business thousands of dollars. The e-Manifest system also allows the EPA to make changes to state regulations and laws in real time.

Safely managing hazardous liquid waste depends on educating communities about the potential risks of improper disposal and encouraging residents to make responsible choices. This can be accomplished through public awareness campaigns, workshops, and accessible information resources. In addition, communities need to understand the importance of supporting sustainable technologies for managing and treating liquid waste.

Site Selection

The site selection process is an important factor in the performance and longevity of liquid waste disposal systems. The right site can significantly influence the type of system used and its ability to meet specific environmental requirements. The right location is also essential for ensuring the proper functioning of the system and for maintaining public health. The first step in selecting the best site for your system is determining whether the area has well water or surface water sources. If your system is located close to a surface water source, you will want to ensure that it is far enough away to prevent contamination. The same is true for well water sources, as a leak from the disposal system could easily pollute the water supply.

In the past, landfill site selection models primarily focused on financial factors, but as awareness of environmental risks grew, more restrictive regulations have been put in place for siting, implementing, and operating solid waste facilities. These regulations require the use of multiple techniques for identifying and prioritizing site selection criteria. However, many researchers have reported that these methodologies do not account for sociological and political issues.

This is because the location of a landfill impacts more than just the environmental conditions. It can have a direct impact on the local economy, ecology, and social and public health concerns. Therefore, it is important to take all of these factors into account when evaluating a potential landfill site.

Another consideration is the distance from main roads. This is crucial because transportation costs can be a significant barrier to landfill site selection. Additionally, landfills near roadways increase the risk of vehicle crashes and traffic congestion.

Treatment

Unlike solid waste, which can be safely stored in containers that hold varying quantities of materials, liquid garbage requires specialized treatment. Businesses that generate large amounts of it must have the means to store, transport and dispose of it in accordance with regulations set by local, state and federal authorities. Those who neglect to follow proper disposal protocols risk environmental disasters and face heavy fines and penalties from regulatory authorities.

Water Contamination: Untreated hazardous chemicals and sewage can leak into vital waterways, contaminating rivers, lakes, and groundwater with toxic pollutants that can harm aquatic ecosystems, poison fish, and cause diseases in humans and animals. Moreover, pollution can reduce soil fertility and make it unsuitable for agricultural purposes. It can also release harmful gases during decomposition, contributing to air pollution and worsening climate change.

Liquid Waste Disposal Methods

The most common method of treating liquid waste is through anaerobic digestion or composting to produce biogas and fertilizers. Other methods include filtration and anaerobic reactors to separate organic matter from the water, as well as oxidation and reduction to eliminate or neutralize the chemical compounds. Advanced treatments like incineration or thermal desorption are sometimes used to completely destroy the substance.

Liquid waste can be sent to sewage systems, municipal wastewater treatment plants, land application, or injection wells. Some treated waste is even used for irrigation to help conserve water resources. Nevertheless, it is important to consider the sensitivity of the liquid waste in order to choose the best disposal method. For example, chemically active substances require special deactivation processes to prevent contamination during storage and transportation. The process of deactivation depends on the nature of the biological agent and the level of sensitivity required, along with local and national regulations.

Disposal

The disposal process for liquid waste is crucial to ensuring that the environment stays protected. If it isn’t handled properly, the waste can contaminate water sources and cause health risks for people who live in the surrounding area. This is why businesses need to carefully consider their options when selecting the right disposal technique.

Liquid waste is a common byproduct of manufacturing and other industrial processes. It can include everything from domestic sewage to hazardous materials like chemicals and solvents. In addition, companies also produce liquid waste when they wash empty containers, such as tote drums and railcars. Even a small amount of liquid waste can create major problems for a business, so proper management is essential.

To make sure that the liquid waste is disposed of safely, it needs to go through certain treatments before it can be sent off for disposal. For example, it may be screened and filtered to remove any debris that is present in the waste. It can then be stored in a variety of places, including septic tanks, lagoons, and holding ponds.

Depending on the type of liquid waste, it can be sent off to be treated and disposed of in a wastewater treatment plant. These facilities specialize in removing the contaminants from liquid waste so that it can be reused for other purposes. For example, sewage could be used to help crops grow by adding nutrients like nitrogen, potassium and sodium.

Using these kinds of techniques for handling and disposing of liquid waste can reduce environmental hazards, save money, and promote sustainability. Moreover, it ensures compliance with the relevant regulations. This is especially important as any kind of non-compliance can result in hefty fines or even legal action.

Sump Pump Installation – How to Install a Sump Pump

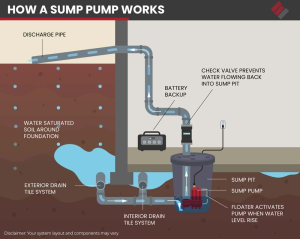

If you live in an area that experiences flooding, having a sump pump installed could be a smart investment for your home. These pumps automatically remove excess water to prevent flooding in your basement or crawl space. They often include a one-way check valve that prevents the expelled water from flowing back into the pit, and they are connected to discharge lines that allow for easy drainage away from your home. You can also choose to add a battery backup power source so that your sump pump remains functional during power outages. Contact Sump Pump Installation Aurora CO now!

To install a sump pump, first dig a hole that is large enough to hold the basin and place gravel at the bottom of the excavation. Then, set the sump pump basin into the hole and pack the gravel firmly around the unit to ensure stability. You may need to raise the sump pump by adding some gravel to the pit or resting it on a paver to achieve the desired height.

Once the sump pump is in place, you can start connecting it to your plumbing pipes. You will need to turn off the electricity before beginning work, and you should wear protective gear for your eyes, ears, and hands. Once you have finished connecting the pipes, you should test the float switch and the discharge pipe to make sure they are working properly.

If you’re not comfortable working with electricity and plumbing, consider hiring a professional to complete the sump pump installation. They will ensure the system is installed correctly and can provide you with peace of mind. If you’re interested in having a sump pump installed, contact a top-rated pro in your area for free project estimates.

Safety Measures

Sump pumps are a valuable tool to have in place to protect homes from flooding, but they must be properly installed and maintained to work effectively. Since sump pump installation involves working with tools and materials that can pose dangers if not handled correctly, it is crucial for homeowners to follow best practices to ensure the safety of everyone involved in the process.

Electrical Hazards

Sump pump installation often involves working with electrical wiring and components, which can pose a risk of injury if not done properly. Taking steps to ensure that all electrical work complies with local codes and using GFCI (Ground Fault Circuit Interrupter) outlets can mitigate this risk. Water-Related Hazards

Since sump pumps are typically located in damp or wet areas, the risk of injuries relating to slips and falls is also a concern. Using proper footwear, keeping the work area as dry as possible, and wearing non-slip shoes can reduce these risks.

Follow Handling Instructions

When handling sump pump materials, it is important to follow the manufacturer’s instructions on how to properly handle them. This will help prevent any accidents or injuries. For example, PVC pipe can be sharp if not handled properly, and cement may create dust that is harmful if inhaled. Therefore, it is essential to wear gloves and face masks when handling these materials. In addition, it is important to dispose of waste materials properly and follow environmental regulations when disposing of them.

Before starting the installation process, turn off electricity to the sump pump and drain any excess water. It is also a good idea to wear eye and ear protection during the installation process.

Once the installation is complete, it is a good idea to test the pump and ensure that it is functioning properly. To do this, pour a few gallons of water into the basin and observe whether the float switch rises and the pump activates. It is also important to inspect the discharge line regularly and ensure that it is free from obstructions, such as ice, debris, or leaves.

Finally, it is a good idea to consider adding a backup power source to the sump pump, such as a battery backup or generator, to ensure that it can operate during a power outage. By following these tips, homeowners can enjoy a safe and effective sump pump that will protect their home from flooding for years to come.

Preparation

Before starting the sump pump installation process, a homeowner should gather the necessary tools and materials. This includes a jackhammer, shovel, power drill, PVC cement, and gravel. It is also a good idea to wear protective eye glasses and hearing protection during the installation. Additionally, the homeowner should turn off the electricity supply before beginning the project.

Sump pump installation can be complicated, but it can also be very useful in keeping the home’s basement dry and preventing flooding. It is particularly helpful in homes that have a history of flooding, are located on a floodplain, or frequently experience wet conditions.

The first step in installing a sump pump is to dig a pit in the basement floor. This pit should be large enough to hold the sump pump and any necessary electrical connections. The pit should also be located in a place that will allow it to easily drain water away from the home.

Once the sump pit is dug, a professional should install the pump in the pit. The pump should be placed in the center of the pit. The float valve should be checked to make sure it is not touching the sides of the basin. A length of PVC pipe should be attached to the pump’s outlet and glued. A check valve should be installed midway up the pipe. This is a critical component of the system because it ensures that water can only flow in one direction from the sump pit to the discharge pipe.

A hose or PVC pipe should then be run from the sump pump to the home’s exterior. A gap may need to be opened in the wall to run the piping. It is important to seal the wall and the piping with waterproof silicone caulk after it is done.

A sump pump should always have a discharge pipe to carry the water away from the house. The piping should be positioned so that it does not create an unnecessary risk of flooding, but should not be too far away from the property line.

Installation

A sump pump can help protect your basement from water damage. Before you start installing the pump, however, make sure you have the proper tools and follow proper safety measures to prevent accidents. Turn off the power supply to the area you will be working in and wear eye and ear protection. Also, be sure to use a GFCI outlet so that you can plug your sump pump into it instead of using an extension cord, which could overheat and cause an electrical fire.

Mark the location for your sump pit and dig it to the required depth with a shovel. After digging the pit, remove any rocks or debris that may be in the way. Line the pit with a layer of gravel that is larger than the size of the sump liner you will be using. This will promote drainage and help prevent the sump pump from sucking up dirt or other debris.

Once the sump pit is ready, you can begin making the plumbing connections. First, connect the pump to the discharge pipe with a male adapter and a female pipe adapter. Apply glue to both and then attach them to the pump. Next, install a check valve between the discharge pipe and the sump pit to ensure that water doesn’t flow back into the pit once the pump shuts off.

Run a discharge hose or span of PVC pipe (with glued joints and elbows as needed) from the sump pump to your home’s exterior. It is important to run the pipe to a point outdoors that will be above ground level and away from your house, so that water won’t flow back towards the foundation. It is also a good idea to add a gate valve halfway up the length of your discharge pipe to keep animals and other unwanted visitors from entering the sump basin.

Finally, test your pump to be sure it’s working properly before you finish the job. The float on the pump should rise and fall easily, turning on and off as needed. If it doesn’t, adjust the float to ensure that nothing is obstructing its movement.